REVERSE ENGINEERING

Reverse Engineering: What is it About?

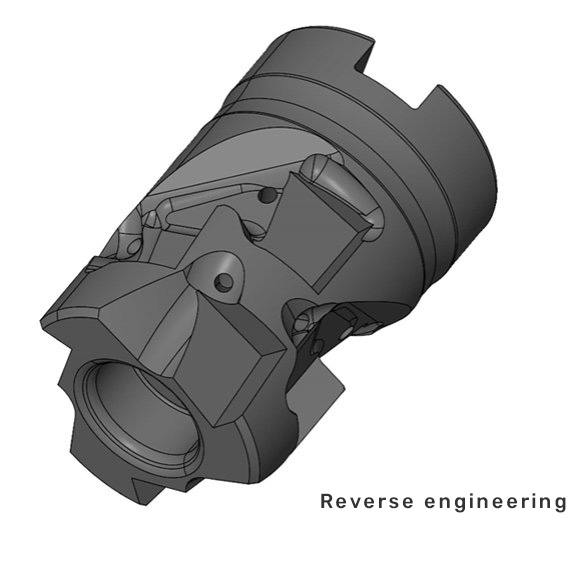

Cor.Sa 3D offers a reverse engineering service. It is a detailed analysis of the operation, the planning and the development of an object with the objective of creating a new one that has the same characteristics as the original, with the only difference being an improved efficiency.

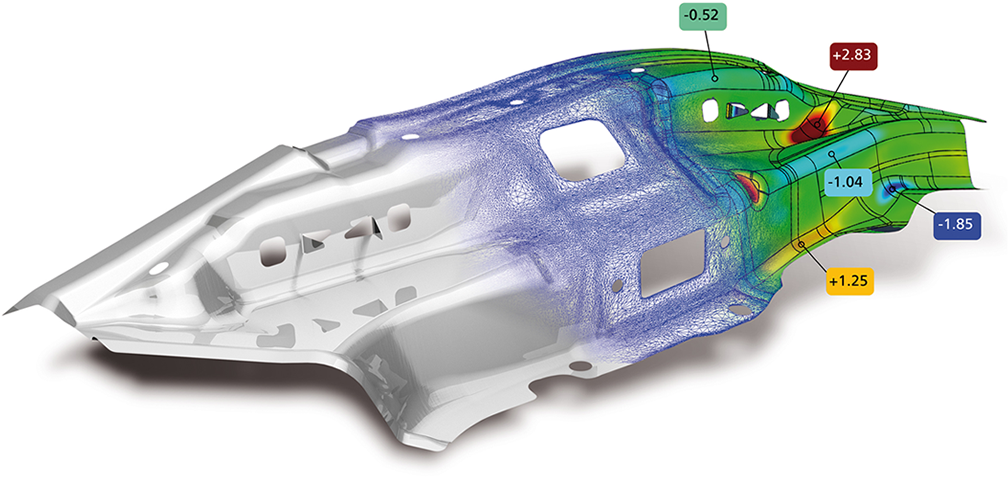

In the field of planning, the term reverse engineering summarizes the whole process of 3D digitization of a physical object to conduct an analysis or to run a computerized remodeling through the use of specific software. To obtain usable files with the most common CAD software (Solidworks, Catia, Cimatron, PowerShape, etc), it is necessary to transform the STL file (cloud points) obtained by the 3D scanning into a file composed of well-defined geometric entities: it is precisely this process that is defined as reverse engineering. In particular, this can be achieved with different techniques and software according to the specific final needs. The most used types of reverse engineering are:

- 3D Parametric Reconstruction: the final file is composed of links,

planes, curves and cylinders recognizable by various CAD software. - 3D Reconstruction for exact surfaces: the file is composed of a series of surfaces that “lie” on the scan as if they were a “skin”. This system is more suitable when the forms are said to be “organic”.

The Phases of the Process of Reverse Engineering

The process of Reverse Engineering is mainly composed of two phases:

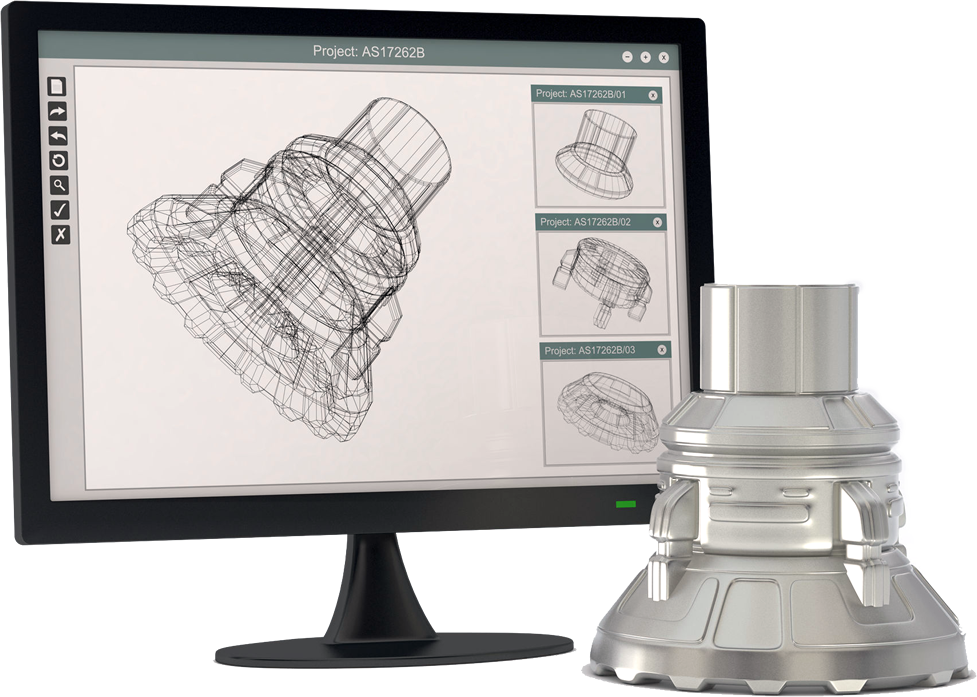

1. Acquisition:

the object is digitalized by 3D scanning (both optical and contact) to obtain a set of continuous points commonly called “cloud points”. To be displayed on dedicated software, it is represented by a series of polygons that connect all of the acquired points between them and thus takes the name of “polygon mesh”. The greater the density of the points, the better the approximation of the “mesh”.

2. Transformation:

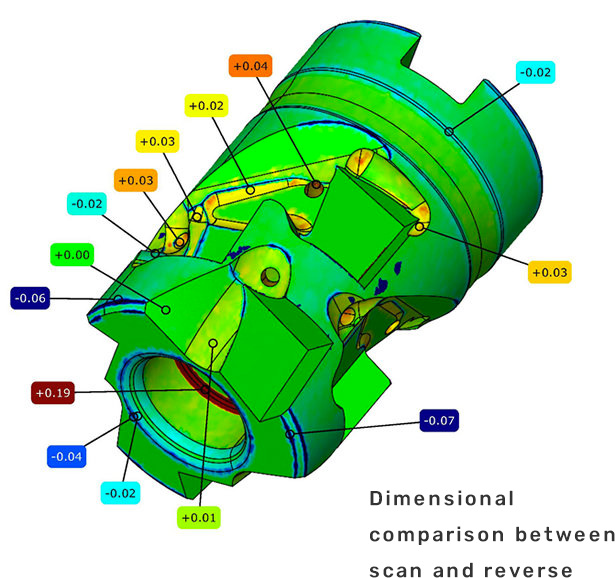

the cloud points of parametric entities is revised by geometrically and rationally approximating the starting “mesh”. The new software dedicated to reverse engineering—like for example Geomagic Design X—allows the carrying out of the solid remodeling directly from the data extrapolated from the “mesh”. In this phase, the possible presence of “background noise”, zones of di discontinuity and distortion of the scan, can compromise the accuracy of the approximation. For this reason, before proceeding with the transformation, it is important to reduce these imperfections with proper instruments.

Areas of Application of Reverse Engineering

3D reconstruction and modeling by reverse engineering have an almost unlimited field of application; in particular, they can be used in the sculptural, industrial, mechanical, aeronautic, aerospace, automotive, civil, architectural and medical industries.

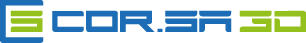

MECHANICS

The applications in Mechanics are the best known but also the most complex because of the industrial sectors in which it is the protagonist. Here constantly evolving CAD/CAM software is used, that provide better and better results and at the same time need tools that are able to best verify them. In this sense, what makes the difference is precisely the optical scanning. The possibility to be able to measure more precisely makes it possible to always be able to push higher in the quality of workmanship. Being able to recover some projects already in progress without having to start again from scratch is an enormous advantage in terms of time and cost, and is therefore fundamental in today’s industrial landscape. Cor.Sa 3D offers a valuable help to mechanical companies that want to increase their level of quality by offering a custom-made reverse engineering service. For companies that produce molds, the possibility is offered—for example—to recover a parametric 3D file from old models or molds not designed for CAD (made with copy milling cutters) from which to obtain a more contemporary digital product. Performing more in-depth dimensional quality control by creating a detailed and personalized report for every need can also be a distinctive sign of the products offered and of the way of working.

ART AND RESTORATION

Already known in this industry, optical scanning makes it possible to preserve or restore luster to those objects that are difficult to restore to their original state. Reverse engineering and 3D reconstruction, for example, are particularly useful in recovery phases where it is not possible to restore the subject because of the poor state of some of its parts: in this case, through the use of a 3D scanner for reverse engineering, it is possible to acquire the portion in question, and then rebuild it, first in 3D and then physically, through the technologies chosen without altering the line and the original charm. Another use of this technology in the arts can be the use of scanning for digital reproductions in virtual museums. In this case the STL file can be covered by the original texture obtained by the scan or by other photographic procedures placed in the responsible space.

MODELING

Until a few years ago modeling was a very limited field: high costs and lack of availability of materials and equipment had relegated it as an activity for few. Today, with the advent of new technologies at relatively accessible costs, the situation has significantly improved. Access to 3D CAD programs, like for example Sketchup, Rhino or opensource Blender, has allowed many enthusiasts to develop ideas and very complex personalized projects.

INDUSTRIAL DESIGN

Industrial Design includes countless areas, including car design, furniture design, yacht design, lighting design. In this field, optical scanning lends itself an effective help to the designer who, after having created sketches and prototypes of his idea, needs to give him concreteness. Cor.Sa 3D takes care of scanning the model and giving the client a printable file with a 3D printer, adjustable and permanent. Every subsequent change to this file may be made on a PC with a CAD program or on the initial model, already having a good basis for subsequent phases of development and production.

Would You Like To Realise Your Project With Us?