Resin Soak

An innovative patent in sand Binder Jetting technology

The exclusive and patented Resinsoak process by CORSA3D represents an innovation in sand Binder Jetting technology, enabling the overcoming of limitations typically associated with foundry use and paving the way for multiple industrial applications.

The use of sand-printed equipment treated with ResinSoak is, for example, employed in the production of carbon lamination equipment, replacing aluminum equipment or milled resins.

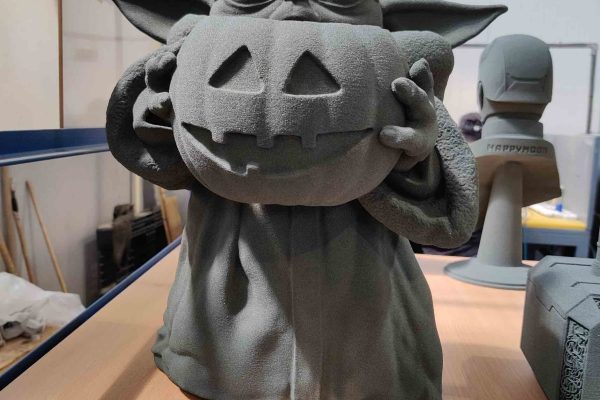

CORSA3D, for an automotive order with an Italian company that manufactures very prestigious cars, enabled the supplier to make the entire car within a month and a half, both the chassis and the body. Lead times using normal procedures would have been much longer.

Also in the automotive sector, 3D sand printing with Resinsoak treatment is thus being used in place of or in parallel with classical methods to make large equipment and models that can then be painted and customized to evaluate shape and style in a very short time and with a 48 percent cost reduction compared to the traditional process.

Hot pressing under press

Resinsoak-treated sand press has been used to do hot pressing under press, resisting the pressure exerted. Therefore, it is perfectly suitable for hot pressing under press molding.

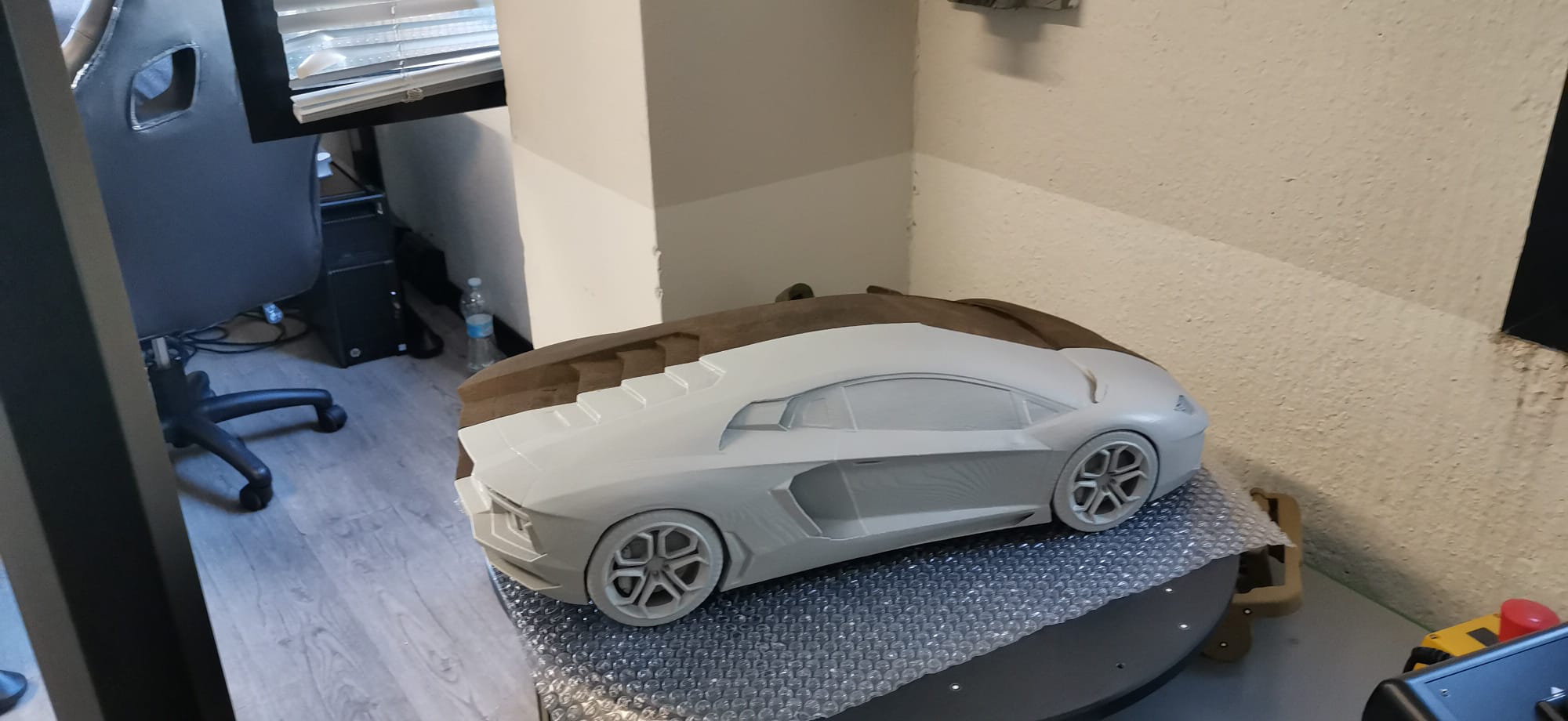

Large-scale prototyping

Resinsoak is also particularly advantageous for large-scale prototyping. Due to the use of sand as a raw material, which has lower costs than plastic polymers for large-scale printing, it makes it possible to obtain objects with good detail with low investment.

Furniture design

Resinsoak also finds use in the design sector, enabling the production of furniture pieces, such as chairs, tables, sofas, and more, which can be sanded, painted, and coated, achieving attractive aesthetic characteristics.

For participation in various trade fairs, CORSA 3D made its own booth material, such as furniture and accessories, in just one week’s work.

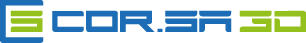

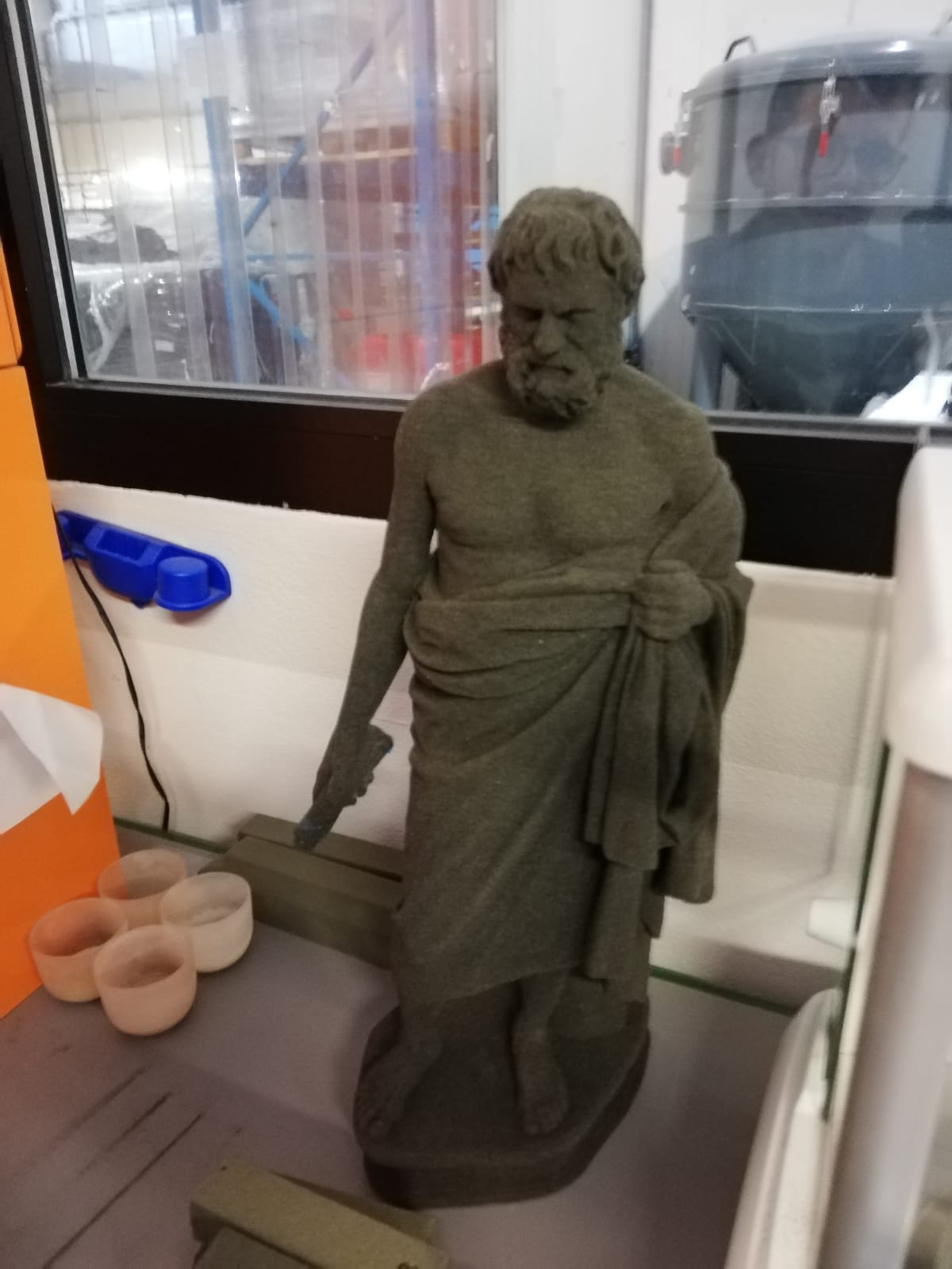

Art and Restoration

In addition to the fields of application mentioned, there are also sectors such as museums that can benefit from the use of sand printing with ResinSoak treatment, for example, for the reproduction of sculptures faithful to the original for use in temporary settings or special events, without the need to move and risk ruining the original statues.

The same principle can also be used for educational purposes, as those who need to learn restoration could start from such objects before working on the actual art pieces.

Building restoration components

CORSA3D has collaborated with architectural firms on the restoration and rehabilitation of historic buildings. In one specific project, the architectural team 3D reconstructed those details that could not be restored, and CORSA 3D printed these objects in sand and then treated them with Resinsoak. These details, when completed, were installed directly on building facades, allowing these original details to be recreated.

Impact on the environment

The use of this method is an example of a concrete commitment to the reuse of materials to reduce the impact on the environment. We are actually talking about objects that are printed with recovered sand from the printing process of foundry equipment, which under normal conditions would have to be disposed of, and in this case is instead used to make the objects that are then coated with the Resinsoak treatment and find applications in very different sectors.

CORSA 3D, with its recycled sand printing and Resinsoak treatment, achieves results that completely meet the needs of customers in many different industries, allowing a significant decrease in cost and lead time.

Would You Like To Realise Your Project With Us?